RESOURCES

TO SHOWCASE

Our latest

references

SINCE AR-VAL’S CREATION, MANY LOCAL AUTHORITIES AND PRIVATE OPERATORS HAVE PUT THEIR TRUST IN US

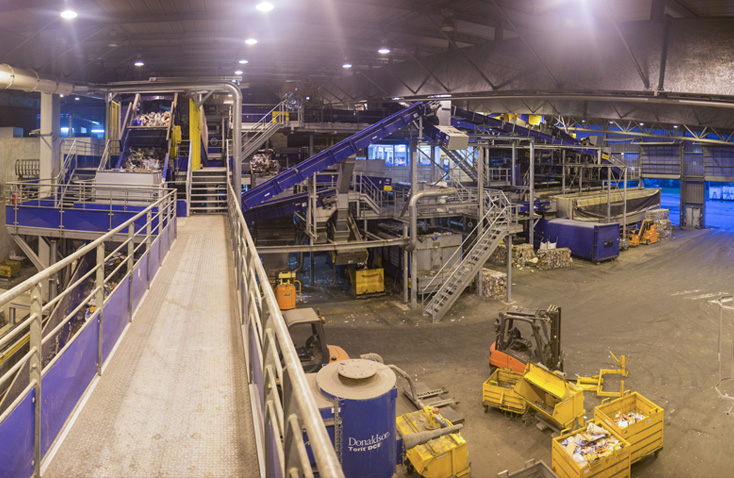

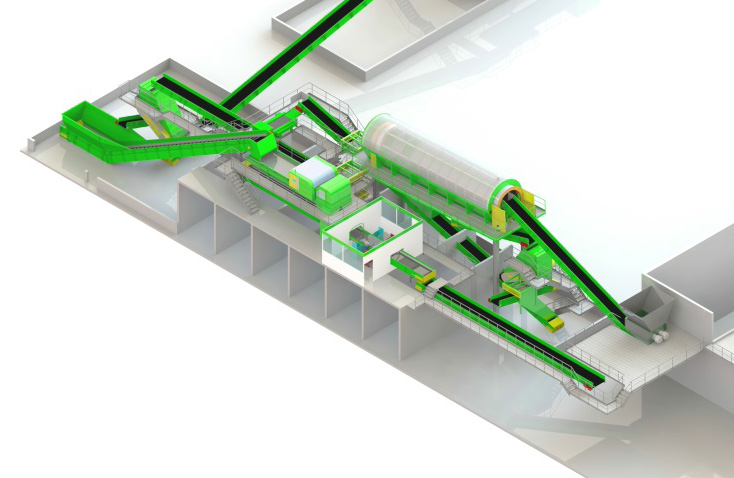

Materials Recovery Facilities, Composting plants, Community Composting units, Refuse Derived Fuel (RDF production plants, Biomass, Waste Electrical and Electronic Equipment (WEEE) and Metal treatment plants, Non-hazardous Commercial and Industrial Waste Sorting Plants, Mechanical Biological Treatment (MBT) plants, Air Treatment… our reference list is long…

FIND OUT MORE ABOUT OUR LATEST PLANTS AND MATERIAL RECOVERY FACILITIES

A few of our clients…

Our products

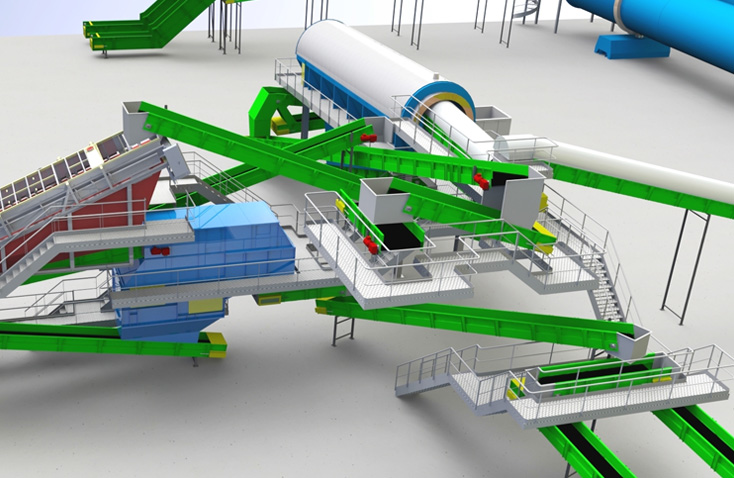

The majority of our equipment is designed and produced in France. In particular, conveyors, metallic structures, frames, trommels and hoppers are produced at our workshop in Anglure.

20 team leaders each manage a team of 2 to 6 fitters. This translates as an assembly capacity of 8500 hours/month, and peak capacity of around 19000 hours/month!

A LIST OF AR-VAL EQUIPMENT

The characteristics of waste, and it’s evolution varies significantly from one area to the next. This is why Ar-Val designs, produces and installs modular process and handling equipment which can be adapted as required to treat all types of waste.

Contact Ar-Val to find out more about its own and its partners complete range of waste treatment and sorting equipment.

A FEW TYPES OF EQUIPMENT

INFEED HOPPER

The Infeed hopper enables the sorting line to be supplied with waste. Equipped with a number of functions, such as throughput regulation and preparation of the flow of waste according to the type of collection and the type of material. It may be equipped with a bag opener, in order to empty bags without damaging the content, and with a weighing system which allows the weight of the material to be checked and recorded.

An example of a Commercial and Industrial waste hopper.

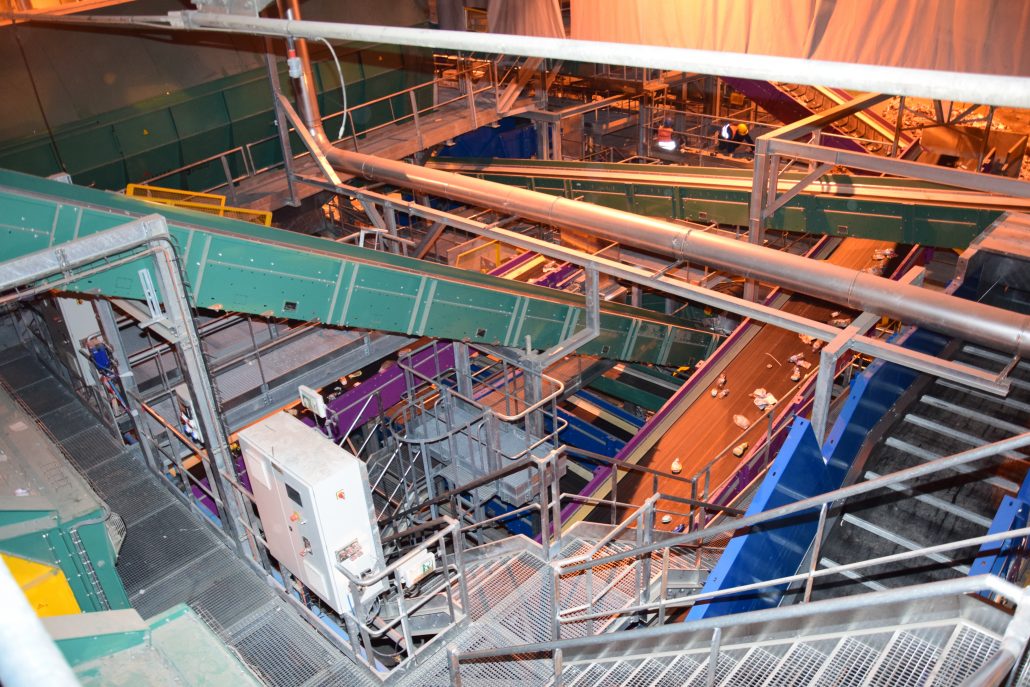

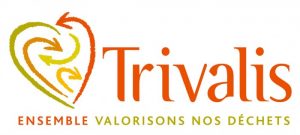

CONVEYORS

This equipment enables the materials to be taken for treatment or to be removed after treatment. Ar-Val designs and produces conveyors for all types of waste.

Example ofa conveyor

Example ofa conveyor

Example of conveyors

INFEED REGULATOR

This device regulates the thickness of the layer of waste material on the belt.

SCREEN

These machines separate material according to size. In some cases, the screen aids regulation of the flow of waste. Ar-Val designs and produces several types of screen, according to the type and fraction of waste to be treated.

FINES SCREEN

This screening equipment extracts small recyclable products.

Example of a fines screen

BALLISTIC SEPARATOR

The Ballistic separator uses the physical properties of the incoming flow to separate the material. Its operation rests on the ballistic properties of the waste to be sorted:

- • 3D, hollow objects bounce on the separator paddles and due to gravity, are evacuated via the bottom of the equipment.

- Flat material which does not bounce move towards the top of the screen.

Examples of ballistic separators

TROMMEL

The trommel is an inclined, rotation drum made of perforated metal sheets, through which material passes and is separated according to size. It is equipped with a speed regulator enabling rotation speed to be modified.

Example of a trommel for sorting residual municipal waste

Example of a trommel for sorting residual municipal waste

BULKY ELEMENTS REMOVER

This screen removes large cardboard objects and / or bulky objects.

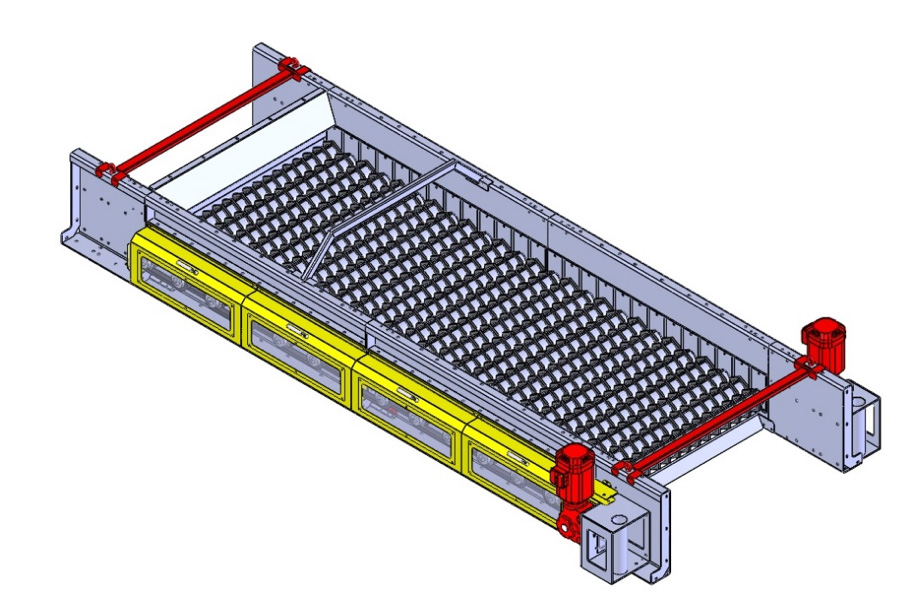

MANUAL SORTING TABLE

It must be ensured that sorting operators have comfortable working conditions in the manual sorting cabin, and sorting tables which can be adapted to all operators, and which meet applicable standards and regulations. For this reason, the sorting tables designed and produced by Ar-Val meet the French X35-702 standard on ergonomics in sorting cabins. This standard defines the requirements which must be included during design of manual sorting cabins for mixed dry household recyclables or similar. The standard relates to the structure, material, space and workstations necessary to carry out manual sorting of waste in a sorting cabin.

Example of a sorting cabin

MAINTENANCE EQUIPMENT

Equipment maintenance and handling in a plant is potentially risky and may be a source of accidents for operators. Therefore, Ar-Val has developed the appropriate equipment to facilitate maintenance for each machine.

Example of a bracket for a Ballistic separator

WASTE CHARACTERIZATION TABLE

Continuous analysis of the composition of the waste to be treated is essential for the operational and production management of a plant. Ar-Val has therefore designed a simple characterization table, consisting of an automatic tipper

Downloads, tutorials & guides.

Access our Downloads, Tutorials and Guides.

Please note: we will shortly make these resources available in English. Please contact us if you have any queries in the meantime.