Resources for innovation

Ar-Val: always at the cutting edge of technology

Discover Ar-Val’s range of solutions for better performance, more simplicity, more peace of mindl

In just a few years, Ar-Val has gained global, multidisciplinary expertise in the waste sorting and valorization sector in France and internationally, with both public and private clients.

Without a doubt this is due to the fact that right from the start the company founders had the necessary expertise to design and produce treatment plants for household and industrial waste.

The managers applied experience gained in the food processing industry and new parameters such as performance indicators, traceability of waste, process reliability, automation and ergonomic considerations were introduced. This was particularly innovative at the time for the recycling sector.

This in turn allowed Ar-Val to develop a complete range of software to optimize the sorting process and to facilitate the monitoring, management, automation and maintenance.

Ar-Val Prod

Ar-Val Prod software allows the complete automation of the installation, the real-time monitoring of its performance, and the real-time configuration of all the equipment.

Ar-Val Gmao

Ar-Val GMAO software is a computerized maintenance management system which allows smart human ressources and material management

Ar-Val Supervision

This software is designed for companies and local authorities who operate waste treatment plants. It allows the operator to manage, configure and accurately measure the performance of sorting lines

Ar-Val Remote

Ar-Val Remote software is a solution to optimize maintenance operations. It allows the control of a waste treament plant whilst it is in maintenance mode.

Ar-Val Mobile

This application allows access to performance indicators for each batch. Production can be monitored remotely in real time on a tablet or smartphone.

CONTACT US TO DISCUSS YOUR PROJECT!

Ar-Val: constantly developing the waste treatment plants of the future

By offering you the best technical and financial answers to your needs.

By designing evolutive, progressive Material Recovery Facilities.

By using our experience in order to optimize our sorting plants and to increase and improve their:

- Reliability

- Performance

- Flexibility

- Productivity

- Optimized maintenance

- Working conditions

Working conditions which conform to the latest standards

In order to optimize the manual sorting operator’s working conditions, Ar-Val offers sorting cabins which follow the French Standard NF X35-702: the best working conditions in terms of health and safety for manual sorting operators.

Our sorting cabins follow the X35-702 standard in order to improve the comfort and working conditions for manual sorting operators, by designing workstations which take into consideration:

- Working position

- Temperature

- Light

- Sound

- Odour

- Vibrations

French Sorting Cabin Standard X35-702

Our sorting cabins conform to French standard X35-702 in order to improve comfort and working conditions for sorting operators.

Focus on the

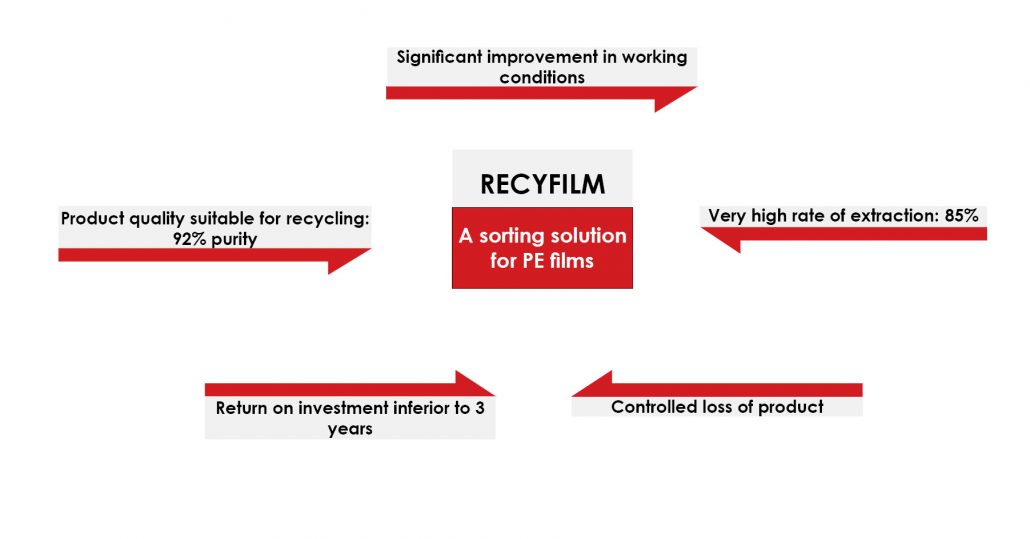

Recyfilms system

A study carried out in France by Eco-Emballages, the public body responsible for waste sorting and recycling, on recycling all types of plastic packaging has highlighted significant difficulties to manually and mechanically sort plastic film. These include the deterioration in the working conditions of operators in the manual sorting cabin, a reduction in throughput and a reduction in the productivity of the process.

To solve these difficulties, Ar-Val, in partnership with Citeo, Valorplast, Tomra and Pizzorno Environnement carried out the design, production and commissioning of the Recyfilms process.

Developed in 2014 by Ar-Val and its partners, the Recyfilms process is installed at many Material Recovery Facilities, including Romainville (Paris, France), CALITOM (Angoulême, France), SMEDAR (Rouen, France), SMTD 64 (Pau, France) and Pizzornon (Grenoble and Le Muy, France).

The Recyfilms Module

Today, the Recyfilms process is the only automated sorting system which can extract Polyethylene films at a rate of purity which is acceptable for recycling (>95% of PE films).

Meeting the challenges

of building a cleaner and more sustainable world.

RESOURCES TO SUPPORT YOU

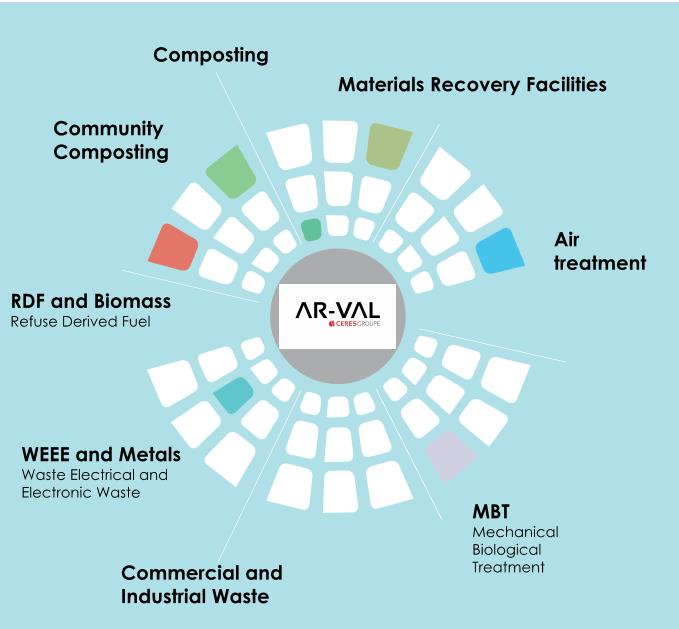

Solutions for different types of waste

EVERYTHING THAT AR-VAL CAN DO

FOR YOU

Whether you are a public authority or a private operator, discover our range of skills and know-how. Our role as turnkey contractor allows us to offer solutions for the treatment of several types of nonhazardous waste and permanently adapt to regulatory constraints and to the flow of waste entering the Material Recovery Facility or Waste Treatment Plant.

If you are a Public Authoritiy, you will of course be well aware of your essential role in successfully meeting the challenge of the green revolution. Waste management and recycling is an essential part in the chain of eco responsibility.

At Ar-Val, we are committed to assisting you at every level: design, manufacture of a new plant, optimization of existing installations, anticipation and integration of regulatory updates both on a technical and human level.

We can accompany and advise you in order to put into place the best solutions for you and your stakeholders.

On the strength of our 17 years of experience of working alongside Public Authorities, our teams here at Ar-Val can offer you the best solutions for waste sorting and treatment. Here are some examples of what we can offer:

Before you begin your project :

- A visit of a Material Recovery Facility or Waste Treatment Plant for a 'behind the scenes' look,

- Brochures and presentations for a better understanding of the waste sorting and treatment processes,

- Discovery of other Waste Sorting and Treatment plants,

- A visit of the workshop where the equipment is assembled,

When you contact us

- Guidance during the planning phase of your Material Recovery Facility or Waste Treatment Plant project

- 'Made to Measure' support from our specialist engineers

- Technical audit of your existing installations

The transition to the use of green energy and resources are an essential consideration for all eco-conscious organizations, whether they are public or private.

At Ar-Val, we offer companies complete, tailored support. We can help you to prepare the design, fabrication, commissioning and maintenance part of your reply to public calls to tender. We can also assist you with your own investment projects for waste sorting and valorization equipment.

Ar-Val has 17 years of experience and a constantly-evolving set of innovations, with more than 70 completed projects in France and Internationally. We are leader on the French market for the design and fabrication of Material Recovery Facilities and Waste Treatment Plants. Always open to new developments, we are constantly diversifying our productions to better meet your needs.

Here are a few examples of what we can do with and for you:

Before you begin your project :

- Visits of existing sorting / valorization plants,

- Visits of our equipment assembly workshop.

When you contact us

- Assistance to prepare your replies to public calls to tender, using tried and tested technical and financial studies,

- Carry out studies, design, construction and commissioning of waste sorting and treatment plants,

- Support you during your Waste Treatment plant project, from the design phase to commissioning. We can also offer operational support after reception of the installations,

- We will ensure that you have an installation which meets European standards, with high guarantees.

Dry Mixed Recyclable Waste

The design and realization of Materials Recovery Facilities is a sector in constant flux, in which Ar-Val is at the origin of a number of important innovations such as:

SCADA

-

- Use of optical sorters to sort plastic or fibrous waste

- Sequential sorting

- Automatic baling

- Ergonomics of sorting stations

- The Recyfilm process

Ar-Val’s teams implemented the first high capacity Material Recovery Facility in France (30 000 t/year) during the a trial to test sorting and recycling a wider range of plastic waste.

Since then, Ar-Val has created several other Material Recovery Facilities designed to deal with a full range of plastic waste:

-

- Calitom and SMTD 65 Materials Recovery Facilities in France

- SYCTOM de Paris Materials Recovery Facility at Romainville (France) with a capacity of 45 000 t/year

- 2016: SMED at Cannes (France), with a capacity of 28 000 t/year

- 2016: SMEDAR at Rouen (France) Materials Recovery Facility, with a capacity of 35 000 t/year

Ar-Val has also modernized and optimized many waste sorting processes.

Composting

Ar-Val Compost Tunnel

Ar-Val’s ventilated, sealed concrete tunnels can be used for composting, biodrying or stabilization, without impacting on the environment of the site.

Ar-Val Top Compost

Ar-Val Top Compost is a system comprised of completely sealed composting tunnels. These robust, industrial structures are easy to install and use.

Ar-Val Compost Cover

Ar-Val Compost Cover is a semi-sealed aeration system for compost production for a limited budget (no buildings) and limited operating costs (no air treatment system).

Community Composting

Community composting

We offer solutions for local treatment and valorisation of organic waste. Composting is the most ecofriendly solution for recycling food waste. With on-site composting, (no transport), the use of the compost as a fertilizer and the resulting plants which absorb CO2, composting has a positive environmental impact. .

Our solution for your organic waste

As approved distributor for Big Hanna composters, Ar-Val benefits from feedback and support from the manufacturer Susteco, which has installed a large number of composters in more than 25 countries.

Between the manufacturer and Ar-Val’s agricultural engineer, we have more than 15 years of experience in community composting. Following research and development, technical improvements have been brought to the equipment.

- • Organic waste is separated and collected at source in the kitchen where it has been generated, and placed in a container or bucket. The organic waste is then placed in the Big Hanna composter where it is turned into compost.

- • The result is a high quality compost which can be used as organic fertilizer for your land. For the best chance of success, a structuring or absorbing material must be added in the form of sawdust, wood shavings or pellets.

- • Depending on the quality of the waste, 10 to 20% in weight must be added. The pellets are mixed with food waste and will not decompose as much as the organic waste. Sawdust or wood shavings can be used instead of granules.

- In certain conditions, garden waste may also be added.

Our community composting projects

UNIVALOM

In February 2015, Ar-Val, approved distributor of Big Hanna autonomous electromechanical composters, installed a T75 model for UNIVALOM in the Semboules area of Antibes (France).

This composter, equipped with a bin lift, a shredder and a biofiltre, is installed at a site which has a shelter for the composter, a covered maturation zone for the compost, and a garden with a educational area. The machine is filled with organic waste from residents and companies in the area, via an organic waste collection point.

ABBAYE DE FONTEVRAUD

Fontevraud Abbey, which became a cultural center in 1975, has implemented a sustainability program. Today, all the organic waste generated by the 2 restaurants, the hotel and the conference center on site are recycled by the Big Hanna composter model T240.

CONSEIL GENERAL DU VAL DE MARNE

The Val de Marne area near the French capital Paris is equipped with two composters. The first was installed in 2014 at Adolphe Cherioux College in Vitry sur Seine, where the restauration service pursued its sustainable waste management program by acquiring a Big Hanna T240 composter. A first for Val de Marne!

In early 2015 the Technical Center at Valenton acquired a T120 with bin lift, biofiltre, maturation zone and wooden shelter for the composter.

SYBERT

SYBERT deals with the waste produced by 230 000 residents in 198 localities near Besançon, France.

A Big Hanna T240 composter was installed in the Young Workers Residence in Besançon. It can also be used by the residents in the surrounding buildings.

The organic waste from the local residents is collected in specific containers 3 times a week, and the food waste from the Young Workers Residence refectory is collected daily and placed in the Big Hanna Composter.

Anaerobic Digestion

Our tunnel-based Anaerobic Digestion system is profitable, easy to install and operate. The process is easy to manage, generating Biogas with high methane content.

The concrete Anaerobic Digestion units are gas proof and supplied with the complete set of instruments, and control and measuring systems. The installation is in compliance with regulations, reliable and safe.

Production of Biogras from a wide range of input material

Agricultural biomass, food waste, municipal solid waste…

E’Cauxpôle Anaerobic Digestion Plant at Brametot (France)

Since March 2015, Brametot Anaerobic Digestion Plant has successfully generated electricity using the fermentable fraction of Solid Municipal Waste.

Non-hazardous Commercial, Industrial and Construction Waste

Ar-Val’s knowhow and experience in the household waste sorting sector is equally applicable to Commercial, Industrial and Construction Waste.

Ar-Val offers a complete range of equipment (screens, shredders) to sort and prepare the material.

Ar-Val has implemented a sorting line for Commercial and Industrial Waste, furniture and bulky household waste, as well as an RDF production line for Suez in Narbonne (France).

With a capacity of up to 60 000 t/year, the installations at Ecopôle de Lambert will be commissioned in December 2017.

Air Treatment

Ar-Val supplies solutions for Air Treatment and Dust removal in order to prevent atmospheric pollution generated by organic waste treatment from creating a nuisance to local residents.

Depending on the situation, we produce biofilters, air filtration systems and dust removal systems.

RDF (Refuse Derived Fuel)

Certain types of waste, such as compost refuse and Commercial and Industrial Waste, have a high energy potential and can therefore be used in place of fossil fuels. Ar-Val offers solutions for Refuse Derived Fuel production.

WEEE (Waste Electrical and Electronic Equipment)

The increase in the price of metals today justifies their separation and purification. Ar-Val works in partnership with equipment manufacturers (optical sorters, shredders, screens) in order to provide ever increased performance to its clients.

Ar-Val, more than 70

completed Material Recovery Facilities.

RESOURCES TO ADVISE YOU

At your side through all the stages of your project

We will do everything

to help you find the best solution

No matter what type of project you are contemplating, our job as turnkey operator combined with our experience will allow us to adapt and conform to all the constraints and specificities of your project.

Whether you are a Public Authority or a Private Operator, our teams will be keen to satisfy you and supply you with the best, most relevant and innovative solutions available with made to measure support during all the stages of its development.

- DESIGN

- COMMISSIONING

- OPTIMIZATION

- MAINTENANCE

- CONSTRUCTION

- MANAGEMENT/SUPPORT

- REVAMPING / MODERNISATION

- EXTENSION

- AFTER SALES SERVICE

Our teams have completed more than 70 waste sorting plants with capacities ranging from a few thousand to 60 000 tonnes / year. Each project we complete in the waste recycling sector is a rich learning experience, supplying feedback to help us to help you to define the best possible specifications for your project:

- Type of equipment

- Recommended process

- Type of intervention

- Required capacity

- Flow of waste to be sorted

- Required purity

All our waste sorting processes are designed with development in mind, so that if required, the installations could be adapted for future changes in the waste to be sorted and recycled.

Ar-Val guarantees a high percentage of recyclables in the different fractions: plastics, paper, cardboard, steel, aluminum, etc.

How we work

Our flexible organization means that each of your projects will be managed by a dedicated business unit, in order to offer you our excellence criteria and to ensure rigorous and effective monitoring from the design to the commissioning phase.

The project manager

Monitors the whole project, remains in contact with the Client’s representative, ensures that the project is carried out to schedule and ensures coordination between all the internal participants in the project.

The design office

In charge of the technical aspects of the project, the Design Office uses CAD software to specify the implantation of the equipment, and manages fabrication and scheduling as specified by the project manager.

Worksite coordinator

Assembly is fully supervised by our Worksite Coordinators. In constant communication with the Project Manager and Design Office, these Waste Treatment Plant specialists are responsible for ensuring the smooth organization of all the phases of assembly of the installations.

They are also responsible for ensuring that correct assembly procedures are followed and supervises assembly from start to finish, and that health and safety rules are upheld on site.

Commissioning Manager

Ensures that the personnel who will operate the new Waste treatment plant receive the correct training, manages commissioning and testing of the different equipment, ensures that configuration is correct and carries out performance testing.

Ar-Val can offer

you operational

support contracts

Because the nature of waste is in constant evolution,

ever more complex configurations are needed for Material Recovery Facilities

Find out more

Our maintenance contracts, to support your teams

All Ar-Val’s After Sales technicians can rapidly intervene on site with their own tools.

Startup and commissioning of installations require specific skills, therefore Ar-Val has put specialized teams into place in order to ensure the most favorable conditions for startup.

WHY CHOOSE US?

Since 2001, Ar-Val’s teams have specialized in thinking outside the box in order to find answers to all of your questions, pre-empt the future of Waste Sorting and Treatment plants, how to be the best at what we do.

Ar-Val is already working on the Waste Treatment Plants for tomorrow’s transition to renewable energy, in response to EU Directives and Public Policy choices to transition from fossil fuels to renewable energies. Improve recycling outcomes, attain better performance in Waste Treatment Plants, limit incineration and reduce landfill.

In France, there is a drive to further industrialize waste sorting by reducing the number of small waste treatment plants and favoring larger ones. In future, there will only be around 100 Material Recovery Facilities in France. This means that increased innovation is necessary in order to rethink the MRF stock and to be able to offer new solutions.

Design

Equipment ordered from us will be designed and engineered by our Design Office.

Our Design team groups around 40 project managers, design engineers and industrial designers who work on the most modern software: 2D software, AUTOCAD, and 3D, SOLIDWORKS.

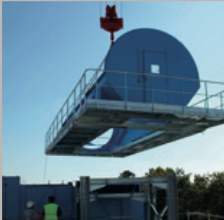

Assembly

Most of the equipment will be manufactured in France at our workshops, in particular, the conveyors, metal structures and frames, the trommel screens and storage units…

20 assembly supervisors will supervise teams of 2 to 6 people, which is equivalent to an average of 8500 hours / month of assembly, with peak capacity of 19 000 hours a month!

Each team is self-sufficient and is has the equipment to carry out the maintenance at our installations.

Our organization allows our teams to be available rapidly, and to be autonomous for rapid, efficient interventions.

The fact that we have our own assembly teams is a significant advantage in terms of efficiency and worksite management.

- No shared responsibility with a subcontractor,

- One person is accountable,

- Well trained teams who are specialized in installing Waste treatment centres will install your waste treatment plant with concern for quality and detail…

On-site assembly is carried out by teams from SOGEFA Group, who have verified experience in assembly work. A worksite supervisor manages the assembly teams, and is responsible for the technical aspects and compliance with health and safety procedures.

Project Committee

In order to ensure the best possible contract management, and to ensure quality, we compose a project committee which is in charge of implementation.

This committee organizes, validates and supervises all the operations regarding the design, construction, testing, commissioning and reception of the sorting process. It applies the principles and procedures devised by our internal quality control department, with regards to:

- Contract review,

- Design supervision,

- Follow-up of the product supplied to the client,

- Identification and traceability

- Supervision and testing,

- Non-compliant products.

All of the above services, production and work is supervised and managed by the contract engineer.

He has direct responsibility over the project operations.

He manages the team which will carry out the design, manufacture, assembly, testing, commissioning and reception.

Contract Review

On receiving an order, the Management organizes a contract review meeting (project startup meeting) during which the future project manager is designated. The aim of this review is to verify coherence between the contract and our quotation. In case of discrepancies, decisions are made regarding the possibility of implementing the contract for the original quotation. If not, negotiations may be held with the client.

After this meeting (or after negotiations), an acknowledgement of receipt of the order is written and sent to the client. It specifies or confirms:

- The scope of supply,

- The schedule,

- The cost of the service.

A confirmation number is defined for the project. It consists of the year of the order, followed by a 3 figure number, for example 2016-050.

This number is used as an internal reference used on all documents (correspondence, orders, clocking hours, drawings…)

Maintenance

Our close collaboration with plant operators allows us to have in-depth knowledge of all the operating constraints, and therefore to better take them into account during the initial design phase.

Therefore, access points are systematically included in order to ensure consistent maintenance of the sorting line:

- Access to motors,

- Access to tension devices (chains, belts…)

- Access hatches in large chutes or inside equipment frames.

Furthermore, we take particular care to standardize common components which are used in different machines (bearings, gear motors…).

This means that spare parts are widely interchangeable and may be available commercially.

For better mobility, our teams of assembly supervisors have their own, fully equipped vehicles.

Modular Design

The implementation of quality equipment.

Our policy leads us to consistently produce robust equipment with inbuilt protective devices (aprons, wear plates, etc…) which require little maintenance.

The feedback we receive allows us to make the best choices to balance cost and quality, and make regular improvements to our materials.

The modular design of our equipment allows many developments over time as incoming waste changes.

Therefore, the following operations are possible:

- Modification of the length of a conveyor, simply by adding or removing an intermediary module,

- Addition of a sorting box,

- Addition of separation equipment…

These aspects are essential in order to face changes in the types of waste collected,

in the recycling and valorization industry, and in sorting technology.

Standards, directives and guidelines

All our equipment are CE certified and meet the EU standards and guidelines.

All of the following procedures are included:

- Protection of reflex angles,

- Protective casings for mobile or rotating parts,

- Emergency stop device for each machine, which will stop the whole line,

- Standard safety rails,

- No rough / sharp parts,

- On the lower parts of the equipment, protection against falling waste / parts.

• Furthermore, our designs include the guidelines issued by the CRAM and the INRS. Since 2008, our filters are ATEX certified under the reference Ex II 3D T80°C – LCIE 08 ATEX 6088 X.

Identification and traceability

Each product is labelled with CE markings which state :

- Year of production,

- Serial number,

- Type of equipment.

Any equipment which is delivered in several parts to be assembled on site receives a serial number followed by a part number.

Subsets and components purchased externally all have an identification plate (a CE plate or the manufacturer’s own identification plate).

The serial number and project number allow all the components of a machine to be traced, using the following archived documents:

- Drawings,

- Detailed records (workshop),

- Orders,

- Invoices,

- Delivery note.

Inspections and testing

During manufacture, inspections are carried out by the assembly technicians or the workshop supervisor:

- Geometry inspection,

- Visual inspection,

- Welding inspection,

- Tightening bolts (torque wrench) for sensitive mechanical elements,

- Paint inspection.

During manufacture, the Assembly supervisor is tasked with carrying out a daily inspection to verify that the correct assembly procedures, the implantation drawing and the schedule are followed.

Non-compliant products

If a product is found to be non-compliant it will be rejected, or an exemption will be requested, if the extent of the non-compliance allows it.

Health and Safety

Health and safety is paramount in our company, and rests on a common mindset instilled by company management in all employees, including temporary and fixed-term contract workers.

Safety during operation and maintenance is integrated in all our equipment at the design stage.

Our workshop tools are renewed in order to include the most effective protection. A Risk analysis committee composed of employees is responsible for identifying risks and suggesting improvements.

At employee level, each new recruit receives Health and Safety training, aiming to share our mindset: do not take risks at work and report any potentially risky situation.

On our worksites, the team manager is responsible for ensuring that safety procedures are adhered to. All our assembly technicians have received specific training (Social Security safety awareness course, First Aid training, Elevated Work Platform training, reading and application of Site Specific Safety Plans, etc….) carried out by external organizations in order to ensure risk awareness and risk prevention methods above and beyond the regulations in force.

un très faible taux brut réel d’accident du travail soit 0,6396 % à comparer à la moyenne de notre profession :

2,60 % (données 2016).

Made in France

Ceres Groupe designs and manufactures its products in France.

The equipment that you order from us will be designed by our Design Office at Anglure.

The equipment will be produced in our workshops by our personnel employed on permanent contracts. More than 75% of the components that we purchase for your equipment will be ordered from French companies.

By ordering from us, you will be participating in the collective effort to develop French industry.

Offering you the finest innovations

and turnkey solutions.

RESOURCES TO MEET YOUR NEEDS

With our After-Sales solutions

Ar-Val services

The logistical and financial cost of the shutdown of a waste treatment plant are such that in 2012 Ar-Val put in place an after-sales department based on availability, attentiveness to our client’s needs, and service.

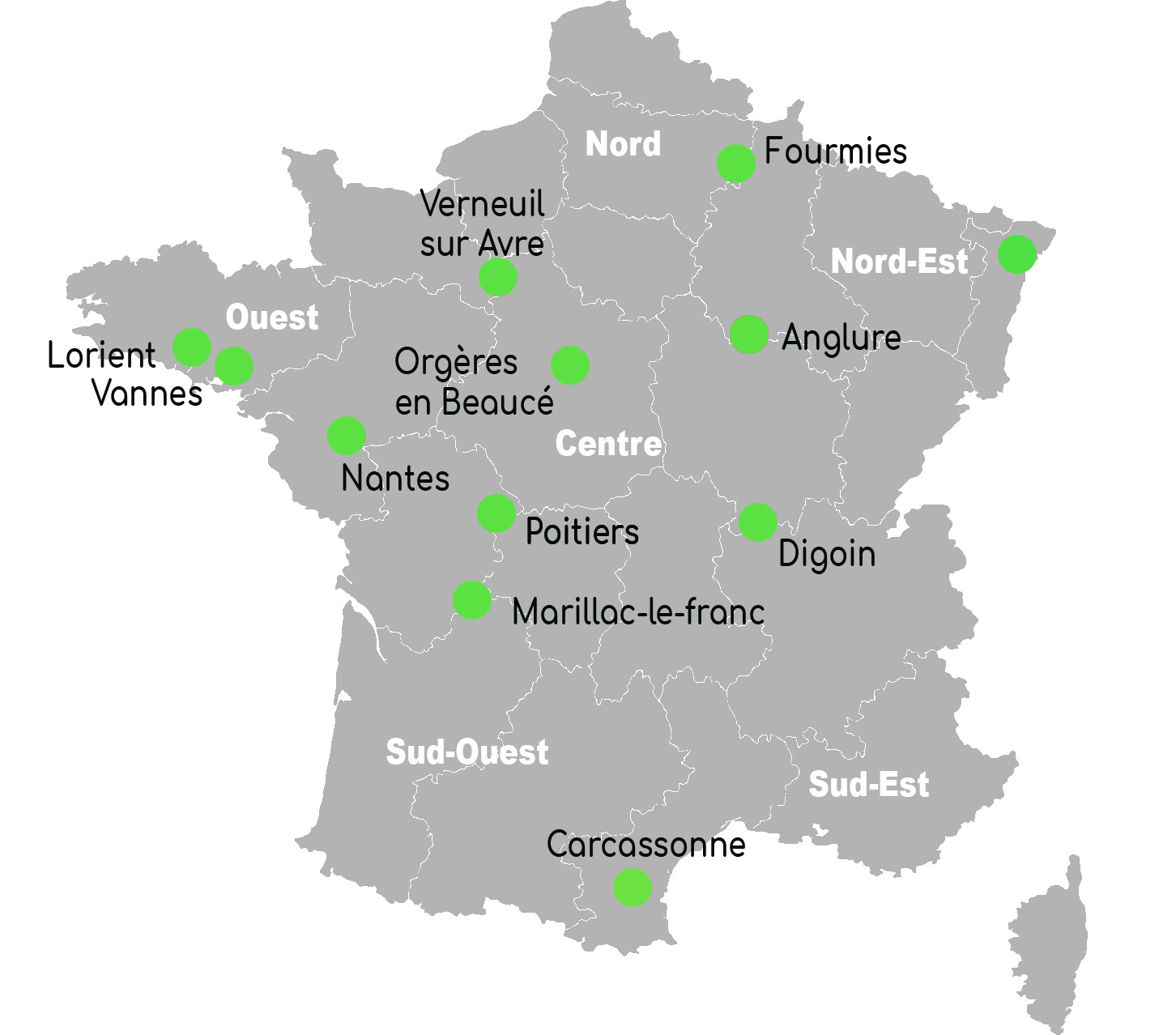

Ar-Val, which is specialized in design, production and installation of waste sorting plants for all types of waste is equipped with a After-sales Department: Ar-Val Services. It’s primary aim is to answer your questions and find solutions for you! For this, Ar-Val can depend on its national network of sister companies, which allows it to be close to its client all over the country.

Since the creation of Ar-Val Services, many clients have put their trust in us.

Disponibilité 24h/24 7j/7 dans toute la France

Nos techniciens sont disponibles sur astreinte ou par téléphone.

Notre réseau de partenaires couvre toute la France.

Ar-Val Services dispose d'un atelier de 600m², d'une capacité de stockage extérieure de 800m² pour les pièces détachées, ainsi que des racks en magasin spécifiquement pour le stockage de pièces de convoyeur (consommables disponibles dans le commerce ou pièces spécifiques).

STOCK DE PIÈCES:

STOCK DE PIÈCES:

Nous disposons de plus de 200 000 pièces et 400 références en stock

- Tambours

- Paliers

- Chaines

- Consommables

- Pièces d'élévateur

- Pièces de convoyeur

- Pièces de séparateur balistique

UNE LARGE GAMME DE CONSOMMABLES POUR LES SYSTEMES DE CONVOYAGE

UNE LARGE GAMME DE CONSOMMABLES POUR LES SYSTEMES DE CONVOYAGE

- Tambours de motoréducteurs et / ou de tension, en dimensions allant de 400 mm 2 800 mm.

- Rouleaux de retour et Blockroll de 100 mm à 1 600 mm.

- Tous types de paliers:

STOCK DE PIECES DETACHEES POUR SEPARATEUR BALISTIQUE

- Arbres - paliers - pales - consommables

STOCK DE PIÈCES DÉTACHÉES POUR TROMMEL

- Roues motrices / libres - paliers

STOCK DE BANDES POUR CONVOYEURS

- Différentes largeurs, longueurs et types

Budget / Prévisions / Production

Ar-Val Services a développé des outils dans les domaines suivants, pour vous aider a maintenir un taux optimal de disponibilité dans vos usines:

- Mécanique (Machines de conception Ar-Val ou de nos fournisseurs

- Electricité / Automatisme

- Hydraulique (Presse balles, presse à paquets, compacteur, ouvre-sacs, quai de transfert)

- Chaudronnerie et soudure

- Levage et manutention / transfert industriel

Contrats de Maintenance

Nous pouvons proposer plusieurs types de contrats afin de répondre à vos besoins: de visites régulières (afin de faire l'état des lieux de vos équipements de toutes marques) à l'externalisation complète de votre maintenance. Nous pouvons vous proposer également une large gamme d'options intermédiaires, selons vos besoins spécifiques.

- MAINTENANCE PLANIFIÉE:

Réduit les temps d'arrêt, remplacement des pièces avant la fin de leur durée de vie.

- MAINTENANCE CURATIVE :

Dépannage / analyse / propositions d'améliorations / devis

- FORMATION:

Connaissances améliorées des outils / prévisions / avancement professionnel. Tous nos programmes de formation sont accrédités par l'Etat.

- Formation de type C: Tri et conduite de ligne

- Formation C10: Différenciation des produits valorisables.

- Formation C11 : Agent de conditionnement.

- Formation C20 : Réglages et conduite de ligne

- Formation C21 : Consignes de tri.

- Formation C30 : Réglages et consignes de tri.

- Formation de type M : Maintenance.

- Formation M10 : Entretien et maintenance des équipements de ligne (type nettoyage).

- Formation M20 : Entretien et maintenance des équipements de ligne (type entretien équipements).

- Formation M30 : Entretien et maintenance des équipements de ligne (type remplacement de matériel).

DOMAINES CONCERNÉS :

Collecte sélective / Compostage / Compostage de proximité / CSR et Biomasse / DEEE / DIB / TMB / Traitement d'air

Nos équipes chez Ar-Val Services ont développé une large gamme d'audits de site, de la vérification de l'état de vos équipements (machine par machine) et / ou vos installations électriques, afin de mesurer la performance de vos usines.

Audits par équipement (état de santé unitaire, sans prise en compte du process)

- Presse à balles

- Presse à paquets

- Convoyeurs / Elevateurs> Ouvre-sacs

- Trémies d'alimentation

A l'issue de ces audits, nous vous fournirons des fiches individuelles de contrôle.

Audits par équipement (état de santé), avec détails photographiques, rapport de visite détaillé, proposition d'une liste de pièces de rechange.

Audits par équipement (état de santé), avec détails photographiques, rapport de visite détaillé, proposition d'une liste de pièces de rechange.

- Presse à balles

- Presse à paquets

- Convoyeurs / Elevateurs> Ouvre-sacs

- Trémies d'alimentation

Audits par équipement (état de santé), avec détails photographiques, rapport de visite détaillé, analyse des futures améliorations possibles sur l'ensemble du process pour la durée de vie des outils

- Presse à balles

- Presse à paquets

- Convoyeurs / Elevateurs> Ouvre-sacs

- Trémies d'alimentation

Ar-Val Services also means :

- Supply and vulcanization of conveyor belts

- Design and improvement of your production tools

- Made to measure, continuous support contract

- Serious references: ECOTRI, VEOLIA, SYSEM…

YOUR CONTACTS

If you wish to contact our After-sales team or arrange a meeting with our Operational Department:

Ar-Val After-Sales Team

Tel : 00 33 2 97 44 44 10

Email : sav@ar-val.fr